I took a look at radiator badges but at $400 for a reproduction, it's not something that I'm ever likely to buy

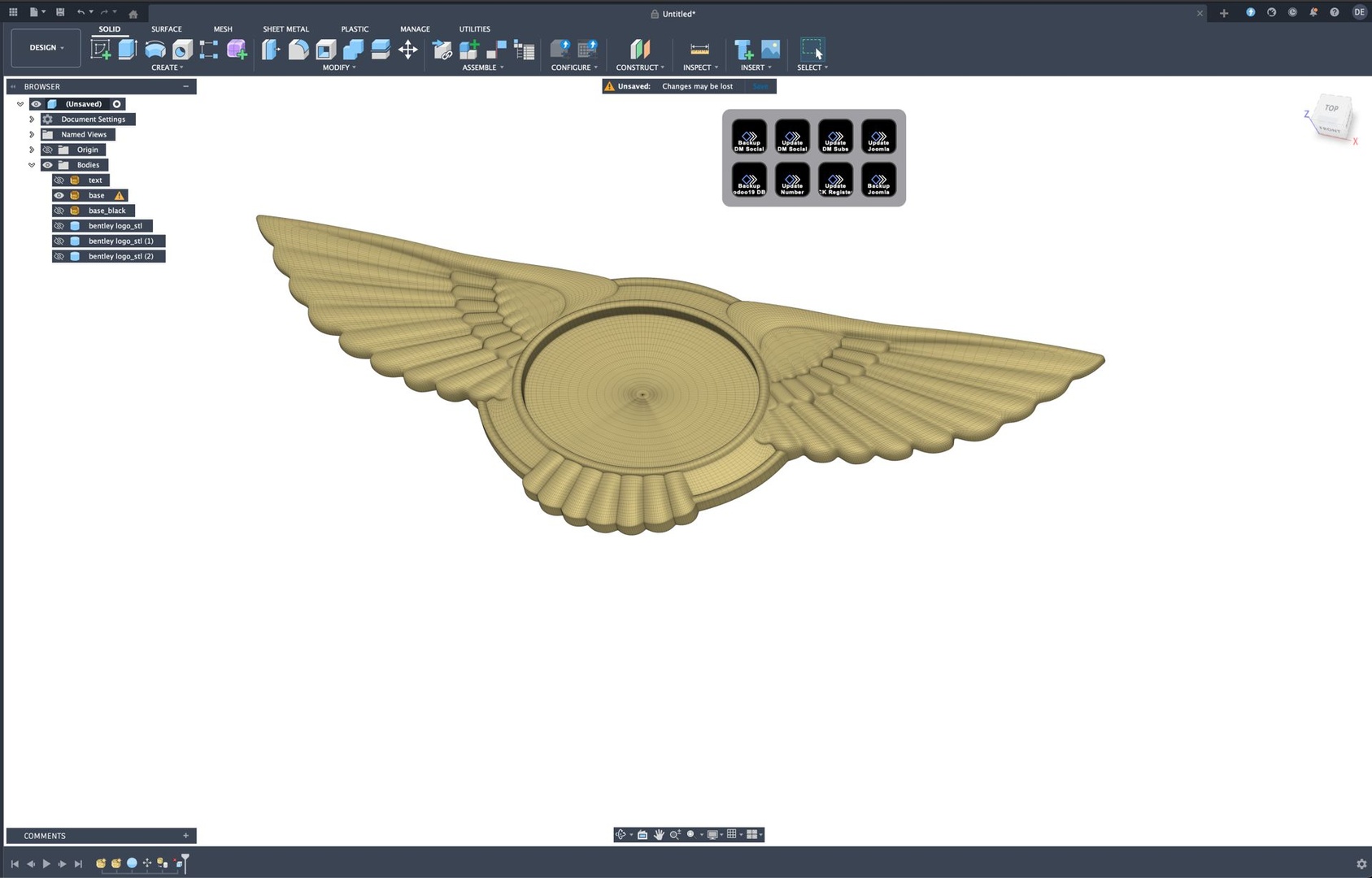

so after a bit of digging, I managed to find a 3D model for one. I actually think it might be a more modern version, but as the design has not changed much in 100 years, it will do fine.

Whilst it isn't shown in the image above, there is also an insert with the Bentley B on it that is part of the model

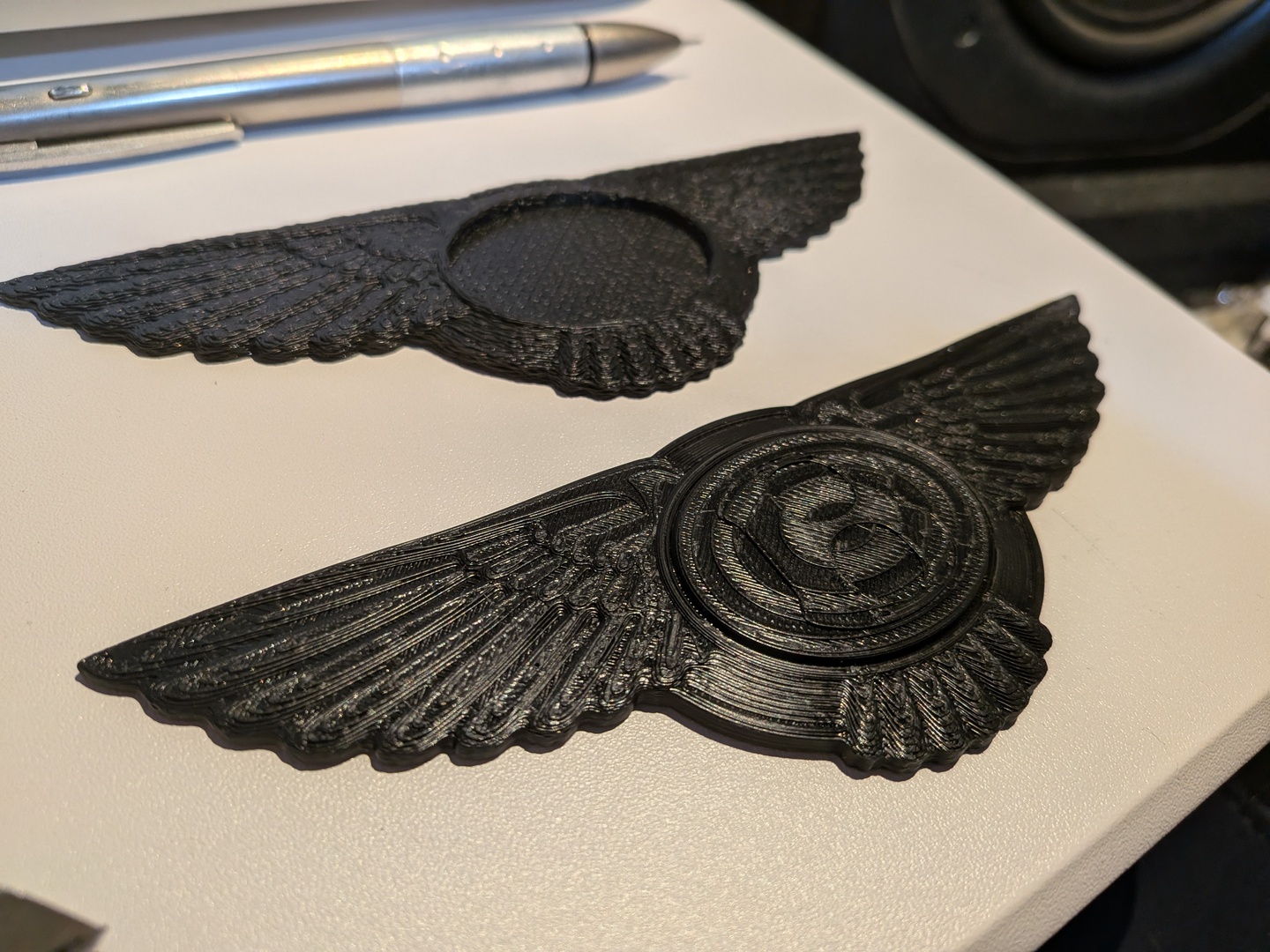

I printed out a couple of different versions on my FDM printer but the quality just isn't there. (and I cannot be arsed to hand finish them - far too much work and a PITA for someone who should wear glasses but refuses to )

I've considered printing one with my resin printer and painting it, but then I remembered that a while back I bought an electric ladle and some pewter to make a badge for another project. A metal badge would definitely be better than a plastic one.

The process is essentially to make a silicone mold from an existing badge using castable silicone, then use it to cast a new badge in pewter. The silicone can grab really fine details and will not melt from the heat of the pewter.

I figure that I can resin print the master and then take a mold from that which I can then cast the pewter in. A bit of a protracted process, but then I'm in this for the journey as much as anything else.

For the centre I think i will cast a laser cut B in some clear resin and cast it in the centre. This technique works really well. I used the same process to make a horn push for the Speedster. I took a silicone mold of the original horn push and then cast a new one up setting a Porsche pin badge in the centre. As you can see the finish is just like glass.

Of course I'm probably getting way ahead of myself, as there's plenty more things to be doing, but it keeps me out of trouble.