It's been a long time since I did any work on the Cyclekart. The house build is still ongoing, I still haven't got the roof on the carport and work has a tendency to consume unreasonable amounts of time. So any plans that I put in place to do work on the Cyclekart always seem to get pushed aside at the last minute when something more important crops up.

So with the upcoming Yesterdays Power Rally event coming up next weekend, I thought that it was about time I thought about putting some bodywork on the Bentley and so have blocked the entire week out to work only on the cyclekart.

First order of business

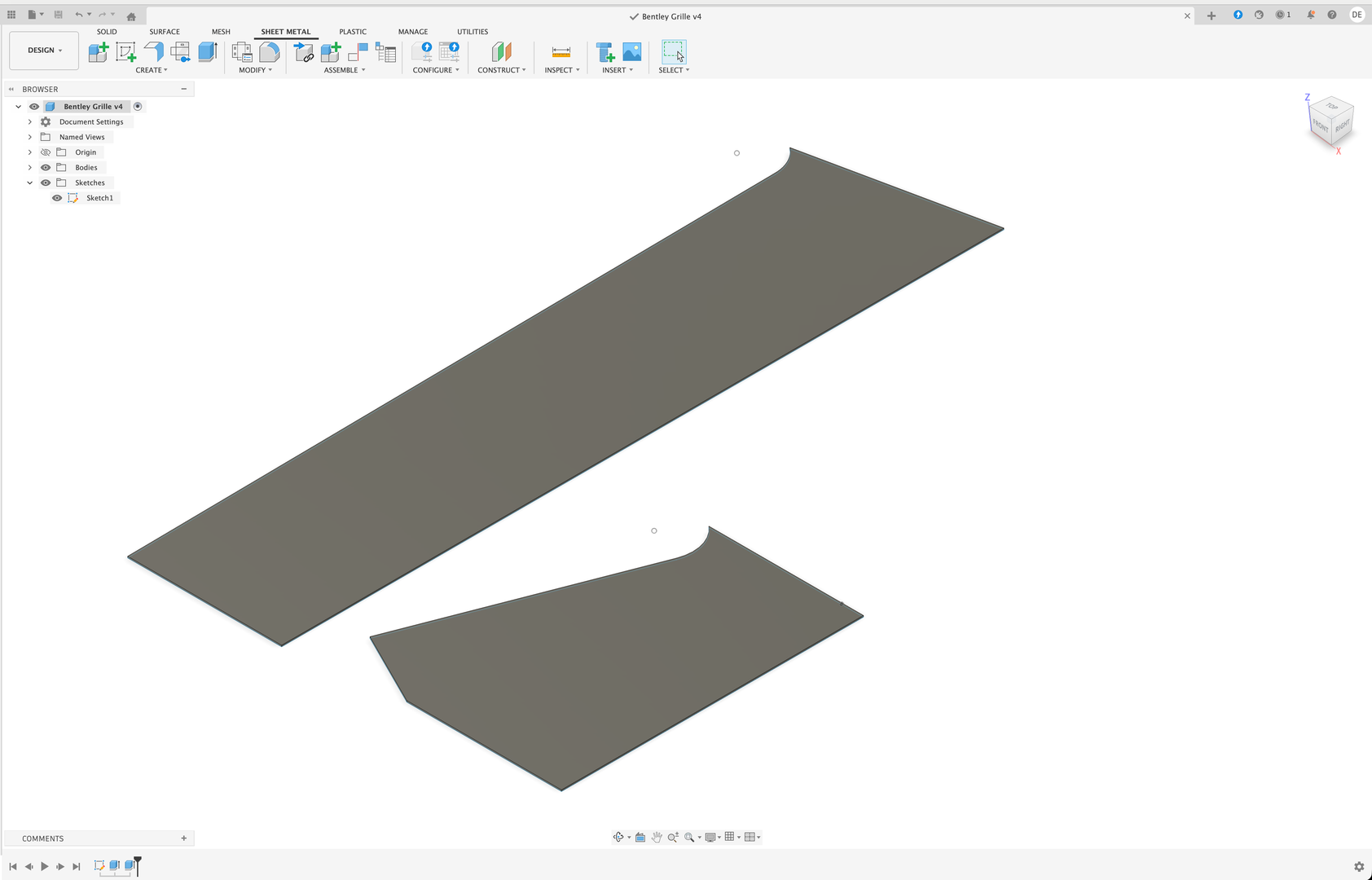

So the first thing that I wanted to do is to get the radiator surround sorted. It's definitely the most complex part of the bodywork and maybe the most important, as it sets the entire aesthetic of the car. Get it wrong and it won't look like a Bentley.

Differences

The SS Jag surround is a little different to the Bentley surround in that it folds back under itself to form a recess where the grille mesh sits, whereas the Bentley has a trim attached to the front which protrudes outwards.

After adding some shape to one of the top parts and test fitting, it was apparent that the angled part of the pattern, which would normally tuck back on itself to form the lip at the centre was not going to work.

Moving Metal

I added some crown to the panel using a blocking hammer. An interesting technique which looks like you've ruined the panel...

But is easily rolled out using the english wheel....

I also added some shrinking tucks to the front edge to pull the front edge downwards

TIP: The trick here is to 'trap the tuck' by hitting the 'root' of the fold. This captures the top of the 'pleat' and then allows the remaining metal along the pleat to be planished into itself, 'shrinking' the metal along the edge. It's a simple technique which anyone can do using a home made 'tucking fork'.

Thoughts and contemplations