Pinned Items

Recent Activities

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

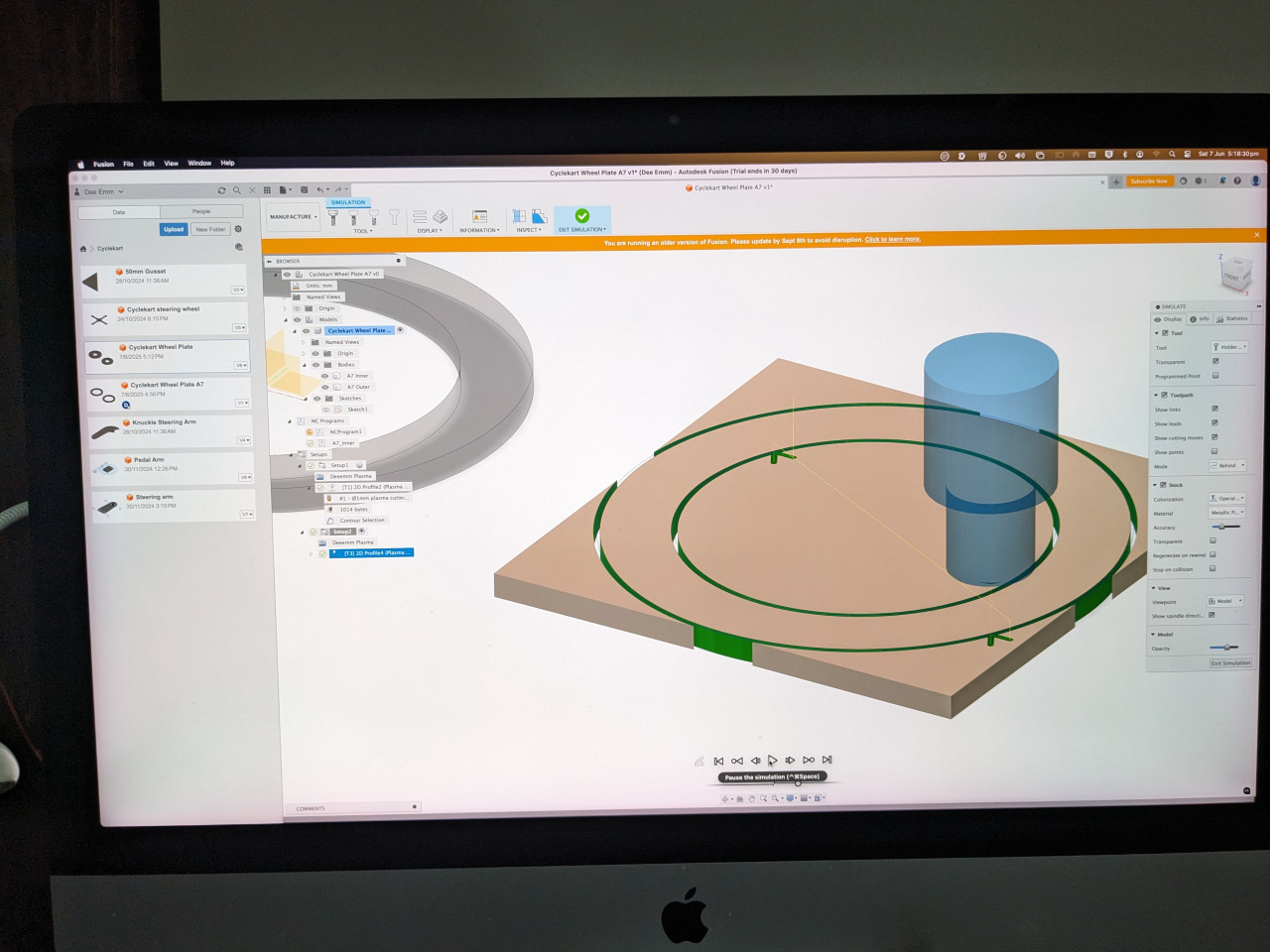

Pete_R reacted to this post about 5 months agoUnfortunately yesterday was raining pretty hard so we spent some time drafting up the adaptors for the wheel hubs and cutting out some parts on the CNC plasma cutter, which kept us in the workshop. Two new skills unlocked lol. Unfortunately there just wasn't enough room to lay the chassis out inside so we decided to put that off until today.

T...Unfortunately yesterday was raining pretty hard so we spent some time drafting up the adaptors for the wheel hubs and cutting out some parts on the CNC plasma cutter, which kept us in the workshop. Two new skills unlocked lol. Unfortunately there just wasn't enough room to lay the chassis out inside so we decided to put that off until today.More

The rain held off today so spent some time today getting the chassis welded up. We decided on the chassis width based on the width of the rear axle, my CK and the width of the front spring. It is 50mm wider than my CK. After we levelled up the trestles, Locke checked the chassis for square and tacked it up. We added some gussets to the front corners to help improve the strength, as there will be a lot of twisting force from the transverse front spring.

Also took some measurements for the front spring hanger ready for a trip to the steel shop tomorrow for supplies. We also need to procure the parts to make up the front beam and vertical links.

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Pursang reacted to this post about 5 months agoSo this is the progress so far....All work done by Locke with a little guidance of course...

He marked out a basic chassis design. It has a large dogleg at the rear to allow the axle to sit underneath. This puts the chassis rail about 100mm above the ground which keeps the C of G nice and low. The front will have a spring hanger welded to the...So this is the progress so far....All work done by Locke with a little guidance of course...More

He marked out a basic chassis design. It has a large dogleg at the rear to allow the axle to sit underneath. This puts the chassis rail about 100mm above the ground which keeps the C of G nice and low. The front will have a spring hanger welded to the cross member for the transverse spring. The spring itself will be inverted, a common modification on Austin 7's to lower the chassis height, so he will be mimicking this with his build.

He stripped the tyres off of the rim, stripped out the hubs and marked out the chassis, which he the cut out in the workshop. Then we laid out the chassis rails and he welded them together. Definitely a natural, his welding is far better than my very first attempts. He also reoriented the torque converter on the engine.

Skills so far - Design. Marking out. Cutting. Deburring. Tyre removal. Hub disassembly. Torque converter assembly. Welding, and of course standing back and admiring your work. lolPost is under moderationStream item published successfully. Item will now be visible on your stream. -

My son has decided to build a Cyclekart for his year 10 school project. He had to undertake a project that included a variety of different skills and problem solving, so a Cyclekart build seemed to fit the bill nicely.

We've been collecting parts for a while now and have already made a start on the chassis.

There is a test and tune day...My son has decided to build a Cyclekart for his year 10 school project. He had to undertake a project that included a variety of different skills and problem solving, so a Cyclekart build seemed to fit the bill nicely.More

We've been collecting parts for a while now and have already made a start on the chassis.

There is a test and tune day coming up next month on the 29th of June so we've set that as the target. He also has a four day weekend starting from tomorrow, so hoping to get a majority of the work smashed out. Aim is to try and get a rolling chassis with the engine mounted.

Parts-wise I already had a set of wheels, tyres, engine leaf spring and an Ikea sink, but we ordered an axle, steering rack, brakes and some other parts from ebay to speed up the procurement process.

The Austin 7 has a transverse front spring setup so only requires one spring. This means I now have enough spare springs to build another Austin 7 lolPost is under moderationStream item published successfully. Item will now be visible on your stream. -

Stream item published successfully. Item will now be visible on your stream.

There are no activities here yet