Pinned Items

Recent Activities

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Spent today working through getting the Cyclekart rolling. This included finishing the hubs for the wheels and the steering.

I had to drill the plates that I cut the other day along with the wheel hubs. I drilled these for M10 bolts. I will need to weld some bits of flat bar to locate the hubs into the wheel to stop the hub from spinning in...Spent today working through getting the Cyclekart rolling. This included finishing the hubs for the wheels and the steering.More

I had to drill the plates that I cut the other day along with the wheel hubs. I drilled these for M10 bolts. I will need to weld some bits of flat bar to locate the hubs into the wheel to stop the hub from spinning in the wheel under load, but I'll do that later. There's plenty of little bits to tidy up before final paint and assembly.

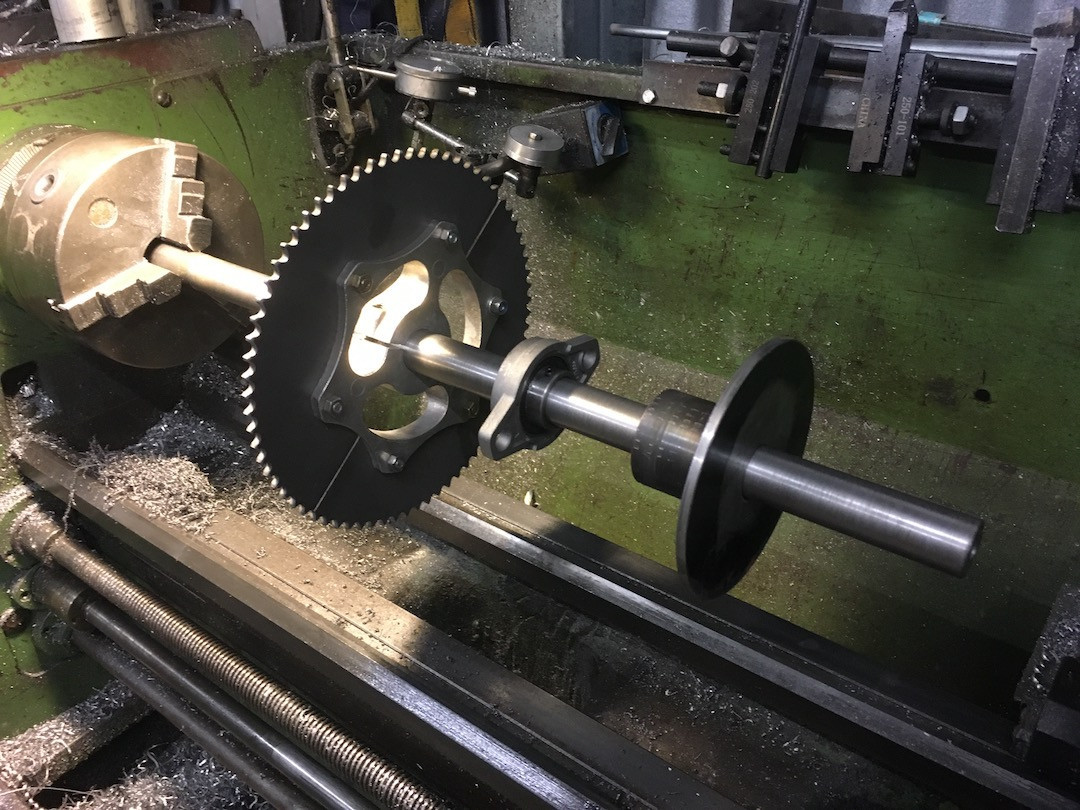

I also needed to clean up the rear axle as the fit of the bearing on one side was a bit too tight. With that done and the axle out of the car it gave me a chance to fit the brake disk. The disk dits nice and close to the cross member at the rear bulkhead, so it should be trivial to mount the calliper. I also have a seperate cable operated calliper as well, this will be operated by the handbrake lever. Handbrakes are a requirement for CCA events.

With the rear axle fitted up I turned my attention to the steering. I drafted up some arms to weld to the front hubs and cut them out on the plasma cutter. Then, literally just I was finished, right at that moment the Amazon delivery guy dropped off the two bearings that I had ordered to mount the steering column. It literally could not have been better timing.

So I made a quick mount for the lower bearing to sit on and a cross bar that I fitted to the dash hoop to mount the top bearing to. I intend to re-do the bottom mount as it is a bit ordinary, but for a proof of concept it does the job. I think I will keep the top mount, mostly as I plan to cover it with the dashboard so it will not be seen. There's plenty of room to slide underneath when getting into and out of the cockpit.

With the steering done and the final position of the dash hoop decided, I tidied up sone other bits and bobs and also fitted the hand brake lever. This sits in line with the dash hoop and will be slightly forwards of the cockpit opening. The cowl will extend past the dash hoop and will curve upwards slightly at the top of the cowl.

I also tacked the rear tail together and tacked it to the rear bulkhead hoop. The tail will be removable, but as I did not get the chance to fabricate the locking mechanism to hold the tail in place, I figured I'd temporarily weld it in position for the show tomorrow.

And so with that done there was only one thing left to do; see if it fitted into the trailer. The trailer is just a 6x4, but fortunately, with the front gate folded down the Cyclekart fits perfectly. The rear chassis member is just higher than the tail gate. Currently the tail section sits above the tailgate but once finished will sit a lot lower. This isn't an issue as It can simply be removed for transport. The trailer was original purchased for transporting the Cyclekart and the fold down front gate was a major plus, so good to see that it fits. One more job ticked off of the list.Post is under moderationStream item published successfully. Item will now be visible on your stream. -

So today was a non-build day as I had other commitments but I did manage to snatch an hour this morning to weld up the steering wheel.

I'm using the typical generic quick release go-kart steering hub to attach it to the steering column. This is an aluminium hub with a steel adaptor that you can weld onto the end of the shaft.

One thing that...So today was a non-build day as I had other commitments but I did manage to snatch an hour this morning to weld up the steering wheel.More

I'm using the typical generic quick release go-kart steering hub to attach it to the steering column. This is an aluminium hub with a steel adaptor that you can weld onto the end of the shaft.

One thing that annoys me about these is the three bolts that hold it on, especially on a steering wheel with four spokes. There's a distinct lack of symmetry to it. So in a bid to make it a little more aesthetically acceptable I decided to add three more mounting bolts. On reflection, perhaps I should have just re-drilled it for four fixings as the original holes would be obscured, and it would have matched the spokes, but foresight appears to be in short supply today. At least with six mounting bolts it has some symmetry to it. I'm not overly keen on the socket head bolts as they seem too modern, but were evidently invented in 1910, so are contemporary with the era. I did have a go at filing a slot in one to turn it into a faux slotted head. But not too sure on what looks best. If I can find some M8 slotted countersunk bolts I'll swap them out.

I also received a delivery for some of the parts I reordered due to not being able to find the ones I already bought. Specifically the brake disk hub and extended hydraulic brake line. Got to hand it to Amazon, I ordered them two days ago and here they are already. Of course. Now that I have the replacements I am almost certain that I will now find the original parts. This being the Law of Sod.

One more day of CK suff before the event on Sunday. Don't expect I'll get anything major done. Lots of shits and bits to finish off tho.Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Today was one of those two steps forwards one step backwards kinda days. I started off with a plan to pick up some more steel to get a start on the bodywork and make a steering wheel so that I could get the steering sorted out. My plan was to roll a hoop from 1" steel tube and use that to make the steering wheel. However, when trying to roll...Today was one of those two steps forwards one step backwards kinda days. I started off with a plan to pick up some more steel to get a start on the bodywork and make a steering wheel so that I could get the steering sorted out. My plan was to roll a hoop from 1" steel tube and use that to make the steering wheel. However, when trying to roll the hoop I found that the rolling machine made a right hash of it. The rollers are too far apart, so trying to roll smaller diameters is a bit of an issueMore

Defeated I decided that I would simply resort to buying a steering wheel. Surely has to be something i could pick up locally eh. Turns out that is a no. Next I decided that I would try and find something with a suitable metal rolled hoop that I could repurpose. Surely there's something in Bunnings that I could use? Unfortunately also a no.

Then I turned to one of my suppliers - a specialist tube benders. Surely they could roll me a simple hoop. Shit, I might even be able to call in a favour. As it happens they could not, but gave me the details of someone who can. I decided to park that as a last resort

So having wasted a few hours I finally decided to reduce the diameter of the tube from 1" to 3/4" and use the secondary rollers on the rolling machine. These are generally used for round bar but go up to 20mm. So I stole the tube I had set aside for the steering column and gave it a test. I managed to roll a reasonable looking hoop. Unfortunately I then needed to go get some more tube to roll another hoop and replace the steering column.

The steering wheel was made from the two hoops welded together. The machine cannot roll a perfect circle. it leaves flat bits on the ends, so to make a completely circular hoop you need to use two hoops and weld them together. Pretty straightforwards. Next I drafted up a basic cross shape for the wheel centre.There seems to be two main styles. One fabricated similar to this and one made from aluminium, so I tried to replicate the profile of the fabricated style of wheel. I also cut out some plates for the bottom of the steering column.

Unfortunately I did not get any further than this as I ended up having to deal with some other non CK stuff which frustratingly turned out to be a massive waste of time. Just the way it goes sometimes.

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

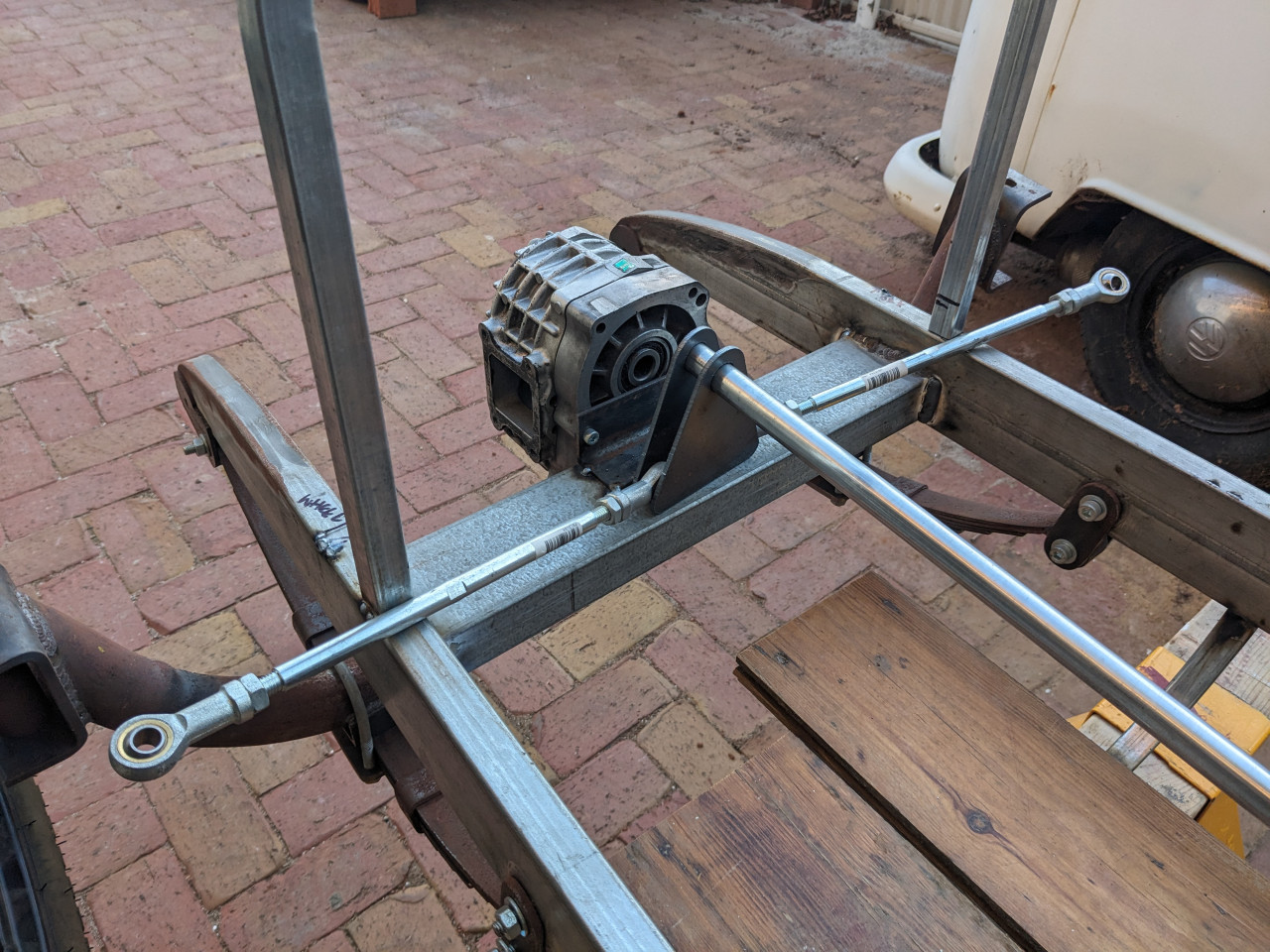

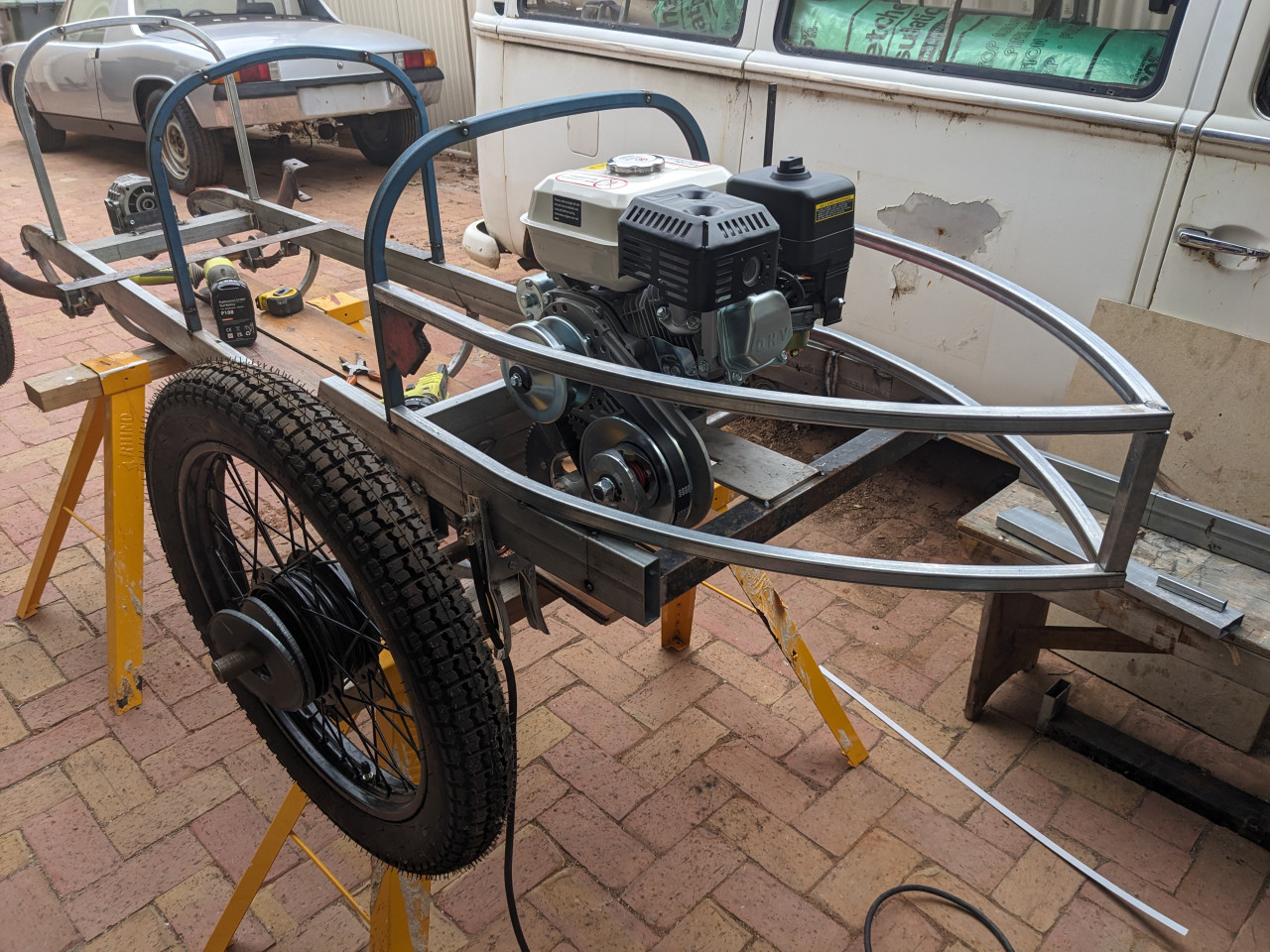

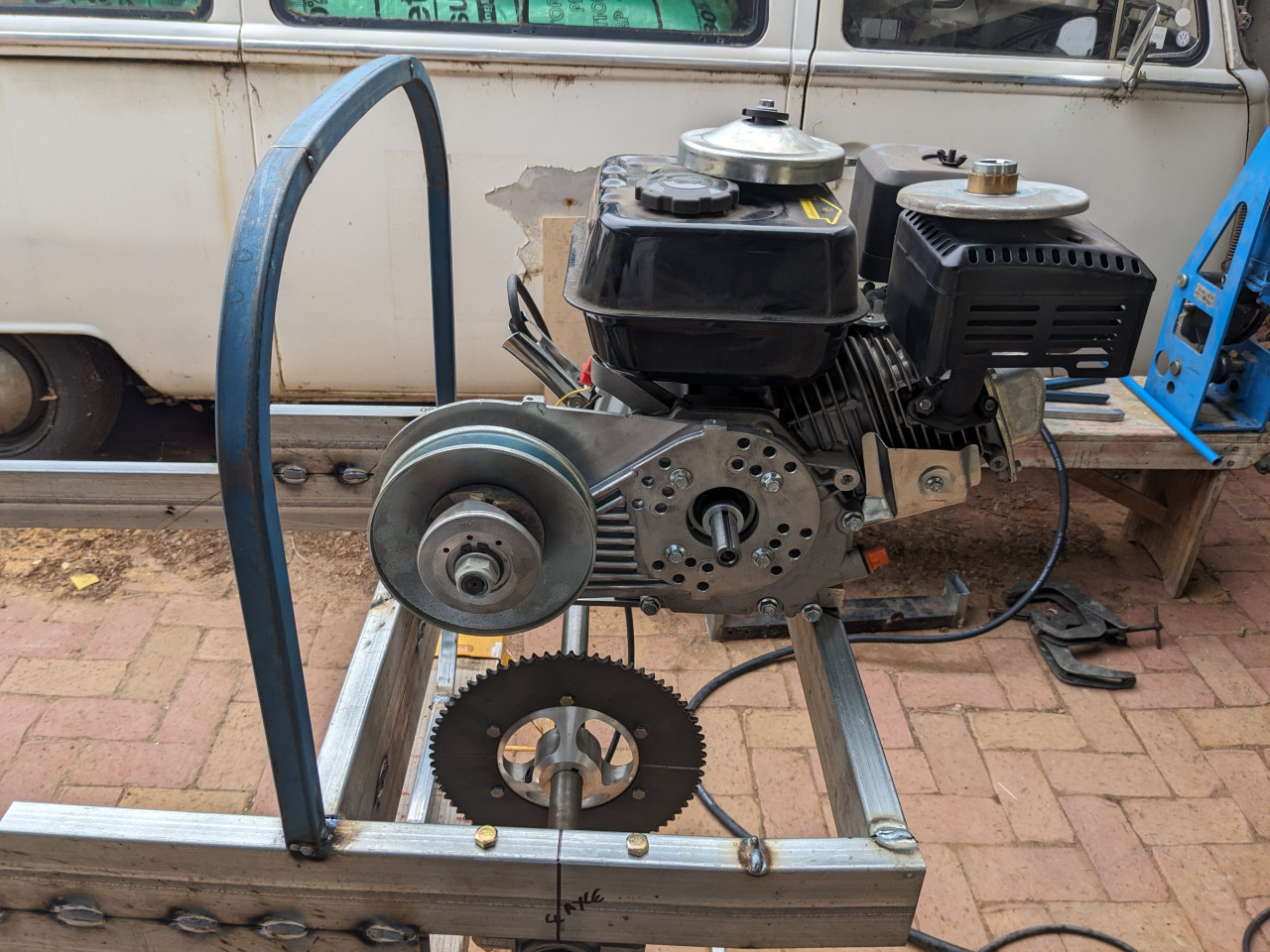

Had a fairly productive day today. After Tim Wheater's suggestions on the FB group to move the engine forwards, I started the day off with bit of a plan in mind. I decided that I should get the tail section made up and then extend the rear chassis to allow me to move the engine further forwards. Making the tail section would define how much...Had a fairly productive day today. After Tim Wheater's suggestions on the FB group to move the engine forwards, I started the day off with bit of a plan in mind. I decided that I should get the tail section made up and then extend the rear chassis to allow me to move the engine further forwards. Making the tail section would define how much room I had to work with. So I mocked up the footprint of the rear tail section with some plastic extrusion and duct tape until it looked kinda right, and then rolled some RHS curves to match.More

After cutting and tacking up the tail frame, I cut out the old rear cross member and extended the chassis rails by 80mm. This was plenty enough room to allow the TAV to be flipped and the engine moved forwards. I also lowered the engine by 20mm, which in turn allowed me to chop the rear hoop by 30mm and still have plenty of clearance above the engine for the body to slope downwards at the rear. I also moved the engine mounting 30mm to the left in the chassis. The reason for this is that now the fuel filler lines up with the centre of the car. I still need to close off the open ends of the chassis extensions, which I will do with some nice rounded off RHS sections, similar to the original, but that will have to wait until another day. I also plan to drop the lower rear tail tube by stepping it just behind the rear chassis member. The plan is to have the entire tail section lift off of the chassis

With the rear hoop chopped, I welded the offcuts on to the dash hoop to bring it up to the same height. I also fabbed up the front grille hoop at the same height as the dash hoop. This really made the outline easier to visualise. It's now much easier to imagine how it will look once it's got some skin on it. It's really starting to take shape.

Moving on to mounting the rear wheels up, I had to draft some plates to fit the outside of the wheels. These act as a reinforcing plate which sandwiches the wheel centre against the rear drive hub and to helps to spread the load of the bolts. This meant drafting up the plates in Fusion360 and then firing up the CNC Plasma. I built this machine over 10 years ago and it's been a pretty handy thing to have. I just need to drill the hubs and plates for he mounting bolts.

With the chassis kinda finished I got a little sidetracked with some accoutrements, which burned up a little time. That and of course the obligatory standing back and staring aimlessly. I managed to reconfigure the handbrake mech that I originally made for my Speedster so that it can be operated from an upright handle. I also dug out a blower casing from the parts bin and mounted that to the front cross member. The grille will wrap around this and I will make up a dummy carburettor and inlet manifold to finish it off.

I didn't get to the steering, but I realised that I need to make a steering wheel before I can get that set up. So tomorrows tasks are make a steering wheel, bend up the wireframe for the cabin and mount the rear wheels. Then with whatever time I have left make a start on the bodywork. Unfortunately I forgot that I have other engagements Friday, so tomorrow is the last hoorah before The Bend. At least it looks kinda car-like.

Ahhh yes. One other very important task for tomorrow. Trial fit it into the trailer. I already know that the Cyclekart is longer than the bed, but that's okay as I can fold the front gate of the trailer down. However I might have to fabricate some kind of transport stand to hold the front wheels up.

Ahh yes, also swapped the engine out for the electric start engine that will be fitted as I needed to make sure that there was enough clearance for the starter

Bit photo heavy this one...Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Today I finished off and welded on the belly pan frames. This also gave me a chance to put a floor in and try it on for size. Everything seems to be good as far as access and ground clearance is concerned. It also gave me the chance to figure out the height of the body and ponder proportions.

The depth of the body at the dash hoop is 600mm,...Today I finished off and welded on the belly pan frames. This also gave me a chance to put a floor in and try it on for size. Everything seems to be good as far as access and ground clearance is concerned. It also gave me the chance to figure out the height of the body and ponder proportions.More

The depth of the body at the dash hoop is 600mm, This is from the bottom of the belly pan to the top of the cowl. This is in line with the Stevensons plans (575mm nominal) and also the overlay that I made. However. The rear hoop needs to be a little higher than this to clear the engine. Plus, the front grille also needs to be a little taller so that it has the right proportions, as currently it is a little too squat. The body lines of the Bentley also have the rear cowl in line or in some cases lower than the front bodywork. Currently the rear hoop is 75mm higher than the front hoop, which obviously does not look right.

I also squared off the rear of the chassis and mounted the engine. It's only tacked in at the moment as I think I am going to try and drop it a little lower in the frame. This will allow me to drop the rear hoop a little, which combined with raising the front hoop will bring everything in line. I'm hoping that this will give the correct overall proportions and be visually correct.

I've got a full day to spend tomorrow so I want to try and get all of the chassis and steering stuff finished off so that its rolling and steering. That will leave me a couple of days to try and get some bodywork on it.Post is under moderationStream item published successfully. Item will now be visible on your stream. -

So I didn't get quite as far as I planned today. But still managed to get the rear bulkhead and dash hoop made up along with the belly pan frames. A fair bit of time was spent getting the tooling set up, which involved searching through boxes trying to find the right sized rollers for my rolling machine and dies for the mandrel bender. Was also...So I didn't get quite as far as I planned today. But still managed to get the rear bulkhead and dash hoop made up along with the belly pan frames. A fair bit of time was spent getting the tooling set up, which involved searching through boxes trying to find the right sized rollers for my rolling machine and dies for the mandrel bender. Was also the first time that I have used the rolling machine since purchasing it a year or so back for another project. So that was kinda cool.More

I did forego making up templates in favour of 'eyeing-it'. This kind of behaviour can obviously go one of two ways lol. Fortunately the profiles came out okay. The trick is to make the bends up in sections and then chop them at the 'apex' before stitching them together, rather than trying to bend them up out of one continuous piece. You do need to plan your bends and also get a little bit of wastage, but steel is cheaper than time so it's a good tradeoff. There is so much variation between the actual full sized cars that a little 'artistic license' is not going to make a big difference. Plus to a degree I'm limited with the radius of the mandrel bender.

I still need to set the height of the bulkhead and dash hoop, but cannot really do that until the belly pan frames are installed. These need to be in place so that I can get judgement of the overall body height from the bottom of the pan to the top of the hood. Scaling from my overlay the dash hoop is supposed to be correct, but it looks a little too low, which I think is just an optical illusion with the belly pan frames missing.

The belly pan frames are simply small hoops that sit underneath the chassis rails to give the sills that rolled under look and drop the floor down below the chassis. I'll weld some 2mm steel plate to the bottom for the floor and extend the bodywork down to meet the floorpan.

Tomorrow I should get those parts stitched up and take a look at the grille hoop. I have a bit of an idea on how to make up the grille surround, but again I'm going to try and wing-it a little as I don't have the luxury of time to build a buck.Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Fixed up the rear chassis section today and got the rear axle mounted up. Mocked up the engine mounting location and tried a couple of difference configurations for the torque converter. I can mount the engine forwards, in which case it would need to be higher to avoid clashing with the drive sprocket, or further back and lower down I'm leaning...Fixed up the rear chassis section today and got the rear axle mounted up. Mocked up the engine mounting location and tried a couple of difference configurations for the torque converter. I can mount the engine forwards, in which case it would need to be higher to avoid clashing with the drive sprocket, or further back and lower down I'm leaning towards further back as the greater head clearance will make the tail easier to make.More

Frustratingly I spent half the day just trying to find the parts that I had stashed. It's been so long since I looked at this project that I could not find everything. Still got some stuff to find.

Tomorrows task is to mount the engine and rear wheels and hopefully get the bulkhead and belly pan frames bent upPost is under moderationStream item published successfully. Item will now be visible on your stream. -

Spent a bit of time digging out the Cyclekart from the back of the workshop today to get it ready for The Bend event next weekend.

After taking check of everything I decided to go back to the drawing board with the rear chassis. The chassis had a bit of a twist in it. I'm guessing that it must have pulled when originally welded and I never...Spent a bit of time digging out the Cyclekart from the back of the workshop today to get it ready for The Bend event next weekend.More

After taking check of everything I decided to go back to the drawing board with the rear chassis. The chassis had a bit of a twist in it. I'm guessing that it must have pulled when originally welded and I never noticed. So I've cut the rear section off and am going with a raised section with the axle underneath, rather than through the chassis rails.Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Stream item published successfully. Item will now be visible on your stream.

-

Brooklands Bentley commented on this post about 1 year agoComments (1)

-

This is kinda cool and a bit like the Pembleton T24 in that its a modern take on a pre-war car. The Bentley Blower Junior is an 85% scaled down More ...

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Brooklands Bentley commented on this post about 1 year agoManaged to score a set of four wheels from Marketplace today. Just $75 too. Looks like CK No. 2 might eventually become a reality. Already have some steel for the chassis and tyres that I previously picked up. Just need to keep an eye open for an engineComments (6)

-

Yeah couldn't believe it. Seemed almost too good to be true. Funny thing was when I picked them up from the fella he said these were the 'last ones'. More ...

-

I pick up about 3 weeks back A 17 inch wheel that look like Honda wheel but the hub is 10 mmm smaller and 35mm bearing 10mm axle with a tyre from More ...

-

Wow. $5 is a bargain. If only everyone could find $5 wheels I think we'd have a lot more Cyclekarts. I'm guessing that you could make that work with More ...

-

I struggled to get a full matching set. Several wheels that I bought where damaged or rusted. A couple had different centres and/or spokes, and so More ...

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

-

Hugh reacted to this post about 2 years agoMail Call...

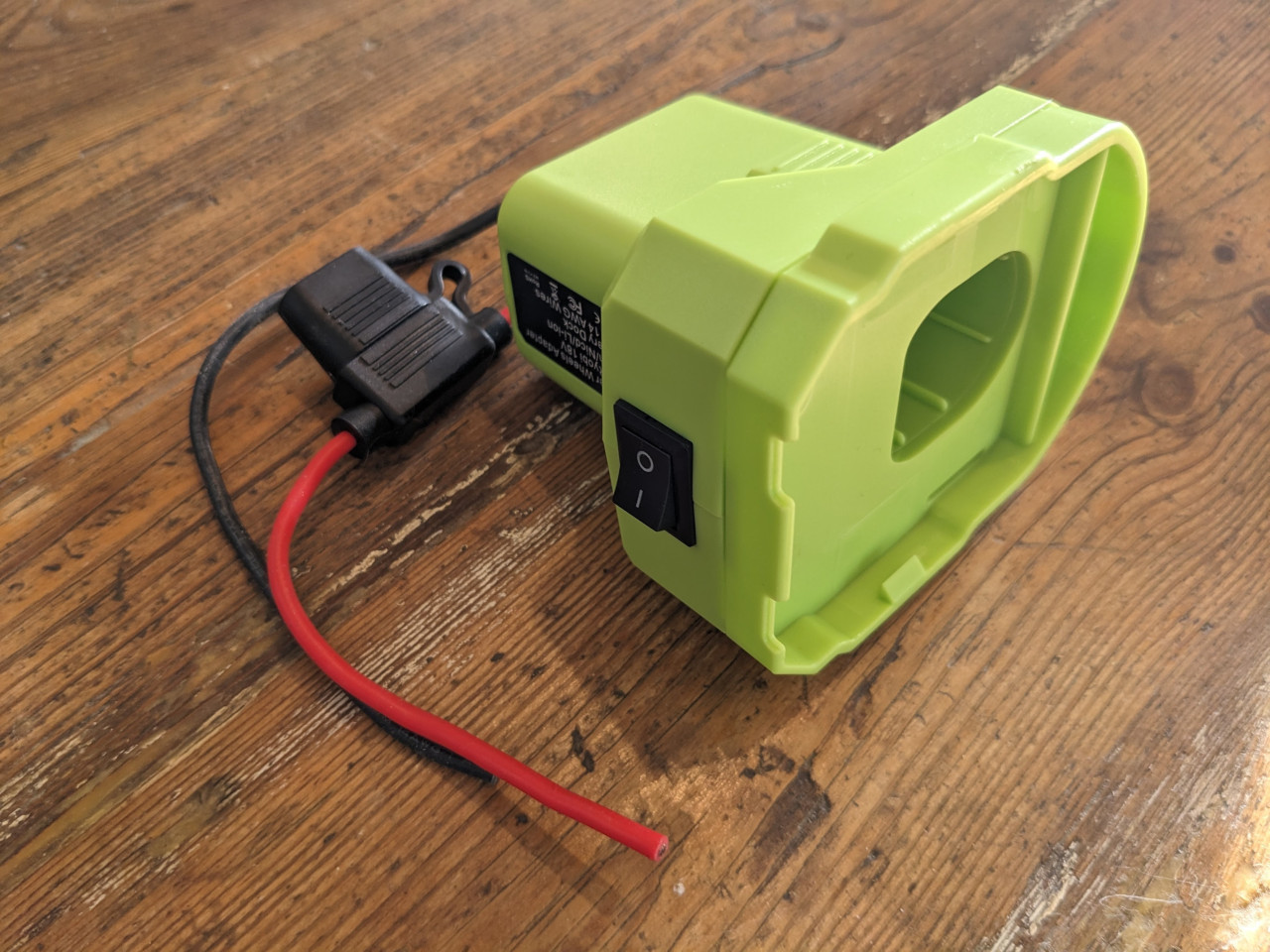

Received another couple of pieces to the puzzle. This is a Ryobi One DIY adaptor and DC-DC converter to reduce the 18volts down to 12volts. This allows you to use a Ryobi battery for the power (electric start / lights / horn etc).

I noticed these parts listed in Steve Vinsons Amazon list that was linked to from his YouTube...Mail Call...More

Received another couple of pieces to the puzzle. This is a Ryobi One DIY adaptor and DC-DC converter to reduce the 18volts down to 12volts. This allows you to use a Ryobi battery for the power (electric start / lights / horn etc).

I noticed these parts listed in Steve Vinsons Amazon list that was linked to from his YouTube videos. It seemed like an elegant solution to a problem I was yet to encounter so I searched for the same parts listed locally on eBay and placed an order.

If anyone is interested here's the parts I purchased.

https://www.ebay.com.au/itm/314275469574

https://www.ebay.com.au/itm/383495785534

The battery holder needs some kind of bracket to stop it from rattling around but that should not be too much of an issue.Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Stream item published successfully. Item will now be visible on your stream.

-

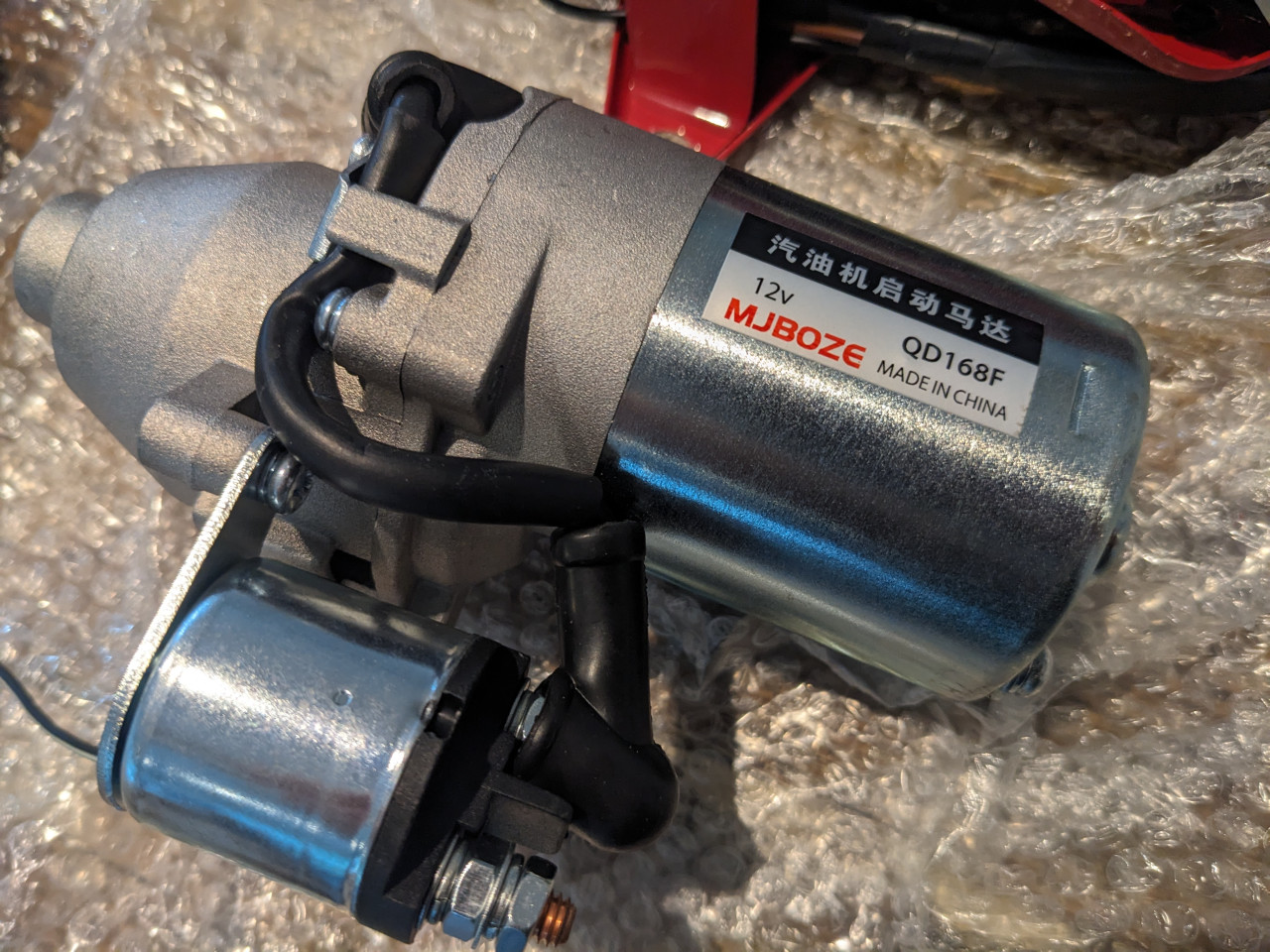

Brooklands Bentley commented on this post about 1 year agoSo with the recent talk of a local event I've been inspired to get back into my Cyclekart build and make an effort to get it finished. so I've ordered the final bits and bobs I need including the engine starter kit which arrived yesterday.

The kit looks straightforwards enough, but doesn't come with any documentation. It includes a new...So with the recent talk of a local event I've been inspired to get back into my Cyclekart build and make an effort to get it finished. so I've ordered the final bits and bobs I need including the engine starter kit which arrived yesterday.More

The kit looks straightforwards enough, but doesn't come with any documentation. It includes a new flywheel, flywheel cover, starter motor, control box and magneto. I need to dig out the engine to take a look at how it all goes together and maybe find some documentation online.

To drive the starter motor I've also ordered a battery adaptor and DC-DC converter to allow Ryobi One batteries to be used. This is a pretty convenient setup as I have a bunch of Ryobi batteries. I also ordered a hydraulic line for the brake caliper and master cylinder I have as well as a pair of headlights.

Interestingly, when I look at Cyclekarts, many (most) do not have headlights. I think that with the Bentley the oversized headlights are one of the defining features so elected to buy some. Will see how they look when fitted.

So next steps are to dig everything out and take check. I still have to finish the rear axle but already have the parts required to do that, I'm also thinking of redesigning the rear part of the chassis. Originally I was using a straight chassis design with the axle running through the chassis but am now thinking of a dropped chassis section running from the middle to the rear with the axle mounted above the rear section. This hopefully solves another issue I was having relating to the engine and torque converter mounting which just wasn't working out as I wanted.

Lowering the rear of the chassis will allow the engine to be mounted lower which will give more options for the torque converter orientation.

Well that's the plan. I'll know more once I've had a chance to dig everything out and do some mockups.Comments (7)-

Don't think this is the same guy but a pretty good explanation - https://www.youtube.com/watch?v=Z5Z6wkCUaY0

-

Which headlights are you going to fit? I am planning on fitting removable mudguards, running boards and headlights to my MGTA.

How did you go with More ... -

I haven't had a chance to fit this yet. Unfortunately been flat out with house renovations so the CK has had to take a bit of a back seat.

I did More ...

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Follow our Facebook page and connect with other Cyclekartistes

-

Brooklands Bentley commented on this post about 3 years agoA little while ago I picked up a tinmans bick, (also known as a tinmans stake). I've been looking for one of these for a few years. I was fortunate enough to be able to trade this for a tool I had two of. It's essentially a small anvil for forming tin or sheet metal. They come in a variety of different forms depending on the specific job. This...A little while ago I picked up a tinmans bick, (also known as a tinmans stake). I've been looking for one of these for a few years. I was fortunate enough to be able to trade this for a tool I had two of. It's essentially a small anvil for forming tin or sheet metal. They come in a variety of different forms depending on the specific job. This one has grooves in it to help form wire rolled edges.More

My plan is to wire roll the edges of the panels on the bodywork in some of the areas such as around the cockpit. I have previously done this way back in my apprenticeship and so decided to see if I could remember how to do it.

You start off bending a small return lip in the panel and then dress the metal around the wire using the groove in the stake. It's not a difficult process but would be almost impossible to do without the stake. You can of course make a similar tool using a block of steel and a file or mill or something similar, but there's something very satisfying about finding and using old tools like this.

One of the main reasons for building the cyclekarts is to try and fine hone my metal shaping skills. I guess this is one step closer.Comments (2)-

Thanks. This was just a bit of scrap I had laying around. I need to try again using aluminium as ultimately I think steel would be too heavy. More ...

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

It's been a long while since I posted anything to my build. Unfortunately I've been recovering from spinal surgery this past year so I've been very limited in physical ability as I get fatigued very easily. As a result I have had to choose my activities accordingly.

I noticed that after an absence of practically a year there does seem to be a...It's been a long while since I posted anything to my build. Unfortunately I've been recovering from spinal surgery this past year so I've been very limited in physical ability as I get fatigued very easily. As a result I have had to choose my activities accordingly.More

I noticed that after an absence of practically a year there does seem to be a lot more interest on the FB page than the last time I was there. That's a great sign. It means interest is starting to build momentum. Now we just need some finished Cyclekarts and some events to travel to.

Back to the subject of cyclekarts and more specifically mine. Unfortunately it got packed away a while back when I had a big clear out of the workshop. So there's nothing to report progress-wise. Things are pretty much the same as they were the last time I posted a year back.

I did make a handbrake mechanism for another project of mine - a Porsche 356 speedster. But amusingly, having made it from photos without a real one to measure from I got the scaling a little wrong and it turned out a bit too large. I need to make a new one in the correct dimensions so this one is surplus to requirements.

Looking at the photo of the Bentley on my project page, I think that it might make a good hand brake mechanism for the Cyclekart. I will need to extend the handle and make up a slightly different release mechanism, but I'm sure I can make it work. Another small piece in the puzzle.

One good thing that did come from the workshop cleanup is that my mill is now properly installed, so I really have no excuse for not finishing off that rear axle. Well apart from needing a suitable sized cutter that is. I'll take a look on fleabay and see what I can see.

I'm still very limited with what I can physically do, but it seems with the increased interest in cyclekarts, now is a very good time to get back into it and get a bit of activity happening on the website.

"Build it and they will come".Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Les reacted to this post about 2 years agoManaged to find a bit of time to finish off the rear hub and broach the keyway. The keyway is cut using a broach which runs in a guide inside the hub. I had to machine the guide to suit the hub diameter, then it was simply a case of pressing the broach through the hub using lots of cutting oil. The broach is spaced out on successive passes...Managed to find a bit of time to finish off the rear hub and broach the keyway. The keyway is cut using a broach which runs in a guide inside the hub. I had to machine the guide to suit the hub diameter, then it was simply a case of pressing the broach through the hub using lots of cutting oil. The broach is spaced out on successive passes using shims until the final depth is achieved.More

Next job is to finish machining the rear axle. I have to mill a slot to accept the key and turn threads on the ends for the axle nuts.

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Comments (1)

-

Finally got me a set of wheels. I picked up these wheels from a fella in Murray Bridge. They are 17" postie bike wheels. Two fronts and two rears. More ...

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

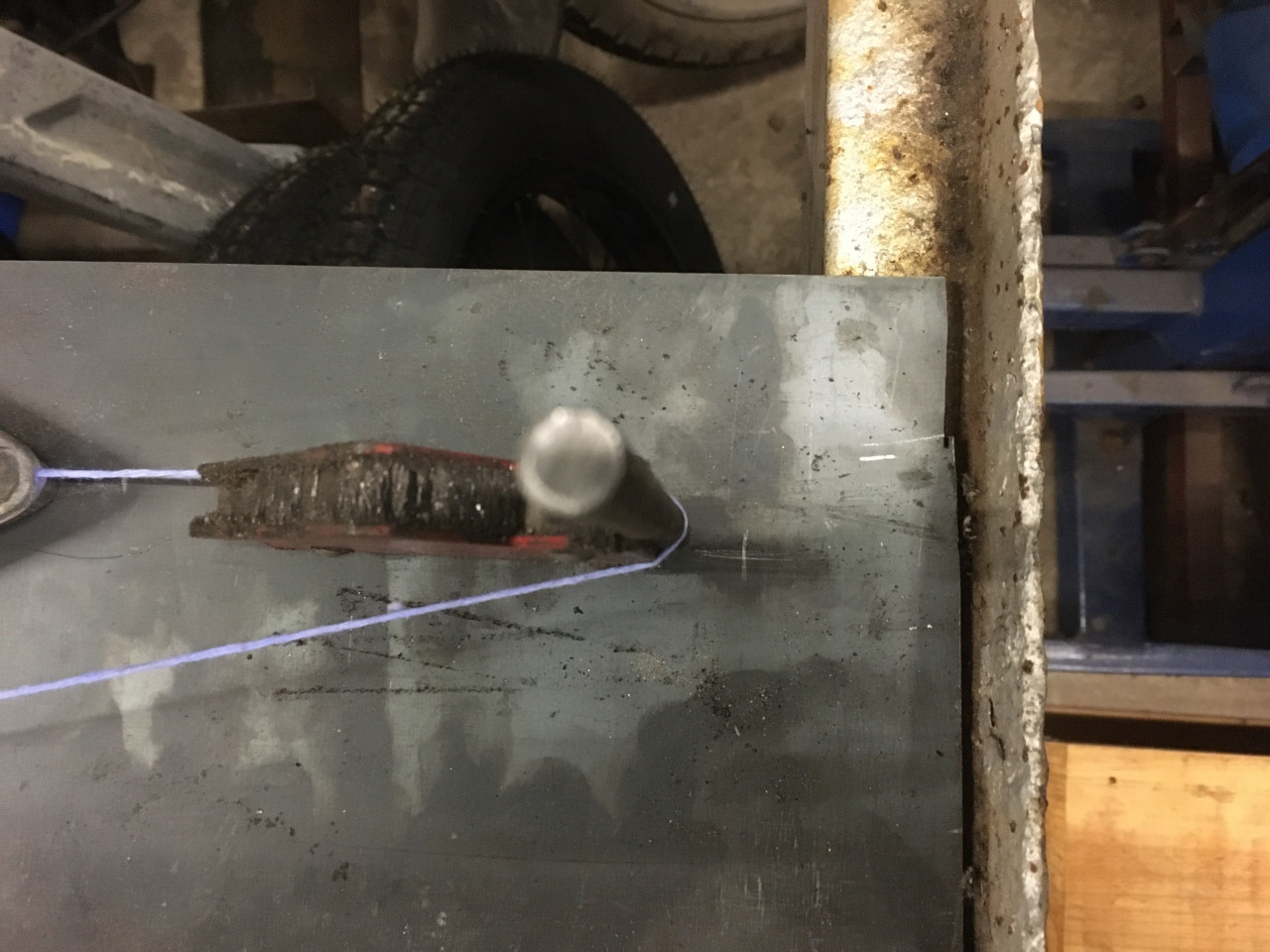

Managed to scrounge half an hour on the cyclekart this evening. I laid out some string to take a look at what I needed to do to get the steering arms made up. The string helps to plot a line from the front steering pivots through the center of the rear axle. The steering arm pivots must fall on this line for the correct ackermann angles.

I...Managed to scrounge half an hour on the cyclekart this evening. I laid out some string to take a look at what I needed to do to get the steering arms made up. The string helps to plot a line from the front steering pivots through the center of the rear axle. The steering arm pivots must fall on this line for the correct ackermann angles.More

I needed to make a curved arms so that on full lock the arms do not interfere with the front beam. I found some suitable flat bar from the scrap pile and set about bending it to make up a couple of arms. I used some heat on the inside of the bend to help 'shrink' the metal. This is better than applying heat to the outside of the bend which will 'stretch' the metal. Shrinking the metal in this way means that the metal is actually thicker on the inside of the bend, which makes it stronger. I also had to straighten it out a little on my bench anvil just to remove some minor kinks from the heating and bending.

The arms will also need to be reinforced with a small gusset underneath to give it some added strength. I will also add a steering stop to prevent the wheel from touching the body, this will be a simple hard stop that the steering arm comes into contact with at the end of its movement. Hopefully I should be able to cut the flat bar in the middle of the bend and make an arm for the left and right sides.

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Finally got around to making a start on the rear axle. I worked out the length, cut the bar stock down and turned one end to size in the lathe. I still need to do the other end and cut some threads in the ends. The drive hub, bearings and wheel hub now fit perfectly.

I also made a start on the motor mount. I cut some plate to span between two...Finally got around to making a start on the rear axle. I worked out the length, cut the bar stock down and turned one end to size in the lathe. I still need to do the other end and cut some threads in the ends. The drive hub, bearings and wheel hub now fit perfectly.More

I also made a start on the motor mount. I cut some plate to span between two cross members, this will support the motor. I'm still trying to figure out the best way to set up the chain drive. I rotated the torque converter downwards to see how the path of the chain was to the drive pulley, but it clashes with the cross member. Need to finalise this before I can move on. So slow progress, but progress none-the-less.Post is under moderationStream item published successfully. Item will now be visible on your stream. -

mainlinemick commented on this post about 5 years agoForgot to post about this. I found some cool looking gauges when I was having a sort through some parts the other day. They came supplied with another project I bought. I'm not going to use them on the other project as they don't really fit with the style, but I think they will look great on the cyclekart. Might even try and hook up the speedo.Post is under moderationStream item published successfully. Item will now be visible on your stream.

There are no activities here yet